Additive Manufacturing

A century of experience in injection molding and extrusion technology provides KraussMaffei a solid foundation for developing additive manufacturing solutions. Additive manufacturing (3D printing), the fourth pillar of KraussMaffei product portfolio, opens up new opportunities for the plastics industry since 2022. powerPrint and precisionPrint are two new systems of KraussMaffei additive manufacturing technology for the production of large-scale prints as well as single-part series production, which will help customers win the future with the high quality.

Product benefits

? Optimize the performance of plastic parts and reduce material costs

? Reduce equipment commissioning and utilization time with generic software solutions

? Increase output efficiency and profitability

? Meet high design flexibility

? Not limited to individual or series production

Product introduction

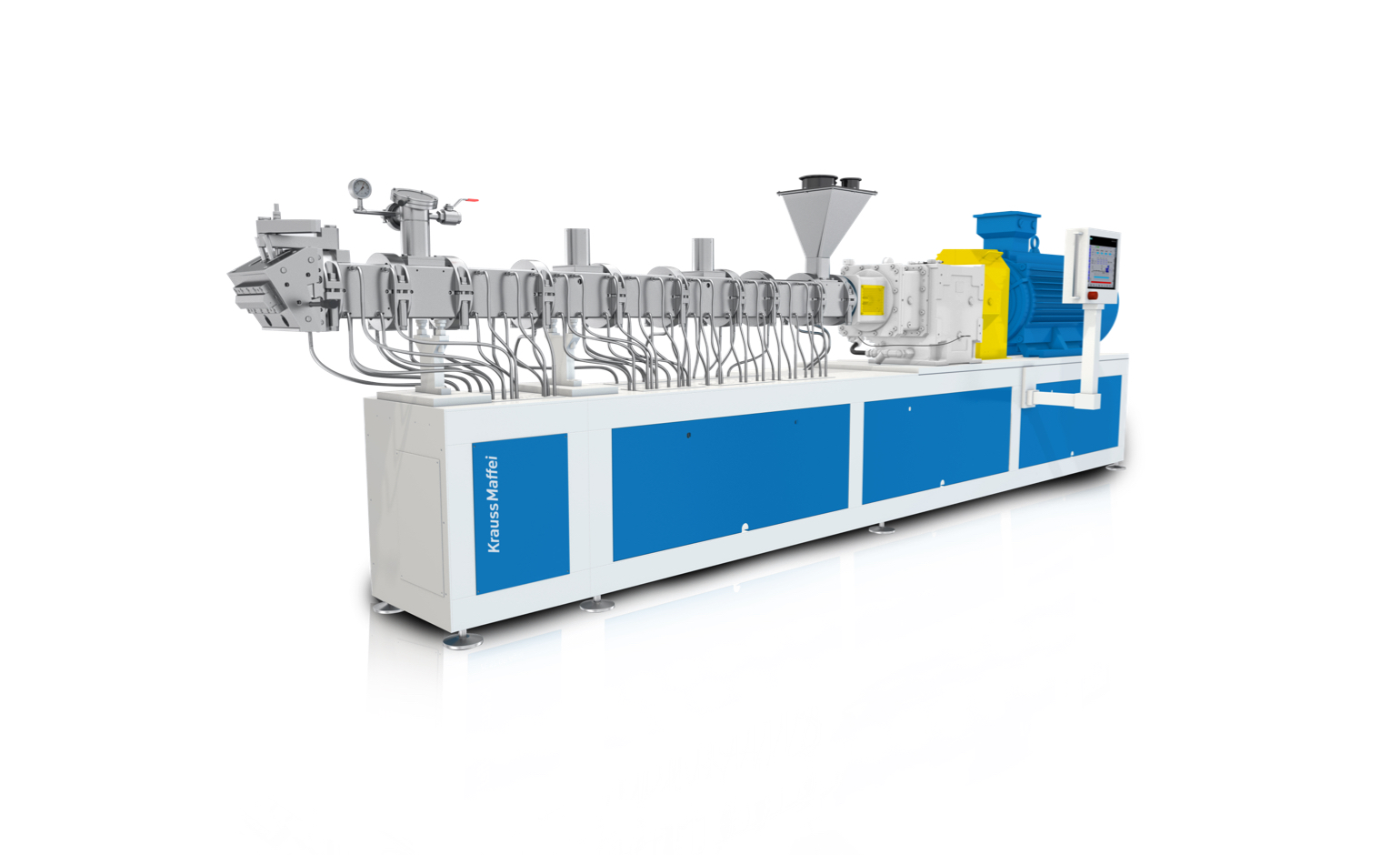

powerPrint is an extruder-based system for processing thermoplastic granulates. For large-format additive manufacturing up to 10 m3, it is the reliable and fast industrial solution, enabling efficient production of near-net-shape components. With precisionPrint, KraussMaffei presents a high-performance SL (stereolithography) solution, suitable for industrial-scale automated production. It is a manufacturing solution with high output rates for the cost-efficient production of plastic parts meeting the highest requirements for

surface quality and detail resolution. The highly automated system uses printing resins cured by laser.

Application area

Medical, electronics and electrical appliances, leisure and sports, foundry industry, furniture and construction, infrastructure, etc.